Welcome once again to our blog

Let’s

get straight to the heart of the matter:

I want to let you in on a little

secret.

I am

a Motorhead.

There,

I’ve said it, it’s now public knowledge.

Many of the hours I’m not working with SmartCAM are spent on my classic cars or other projects.

Many of the hours I’m not working with SmartCAM are spent on my classic cars or other projects.

You

know, I have a hunch that many of my colleagues are also Motorheads. Just that they

haven’t yet admitted as much.

What

has that to do with a blog site about SmartCAM CAM software, I hear you ask.

But bear with me, we will get to that.

Sunbeam

Rapier Gearbox

One of

my recent projects was to strip down, check and re-assemble the gearbox of my ’62

Sunbeam Rapier. It had a really noisy ‘rattle’ in first gear.

I took some photos of my work in my dark garage. They're a little fuzzy but do the job.

|

| The Gearbox Casing |

|

| Mainshaft, 3rd and 4th, plus selector rods and a couple of synchro rings |

For

years I avoided working on gearboxes, which are full of shafts, gears, bearings,

thrust washers springs and other stuff. They seemed just too complex to work

on.

But this

is now my second gearbox strip-down. A couple of years ago we – my son and I –

stripped and repaired the gearbox of his Land Rover Series to cure an odd

rumbling noise. They aren’t so complex after all.

|

| Casting date - 3rd May 1962 |

|

| Selector forks and other bits |

But

they can be tricky. The Rapier gearbox layshaft, for example, has to be temporarily fitted

with a dummy shaft of exactly the right length, dropped into the bottom of the

box before fitting the mainshaft and then the box inverted to hopefully use gravity to convince the layshaft to mesh and drop into its correct position before driving

the dummy shaft out using the proper shaft.

The dummy

shaft had to be turned to precisely the right length – the layshaft plus abutment ring. That little lot was an exact fit between the thrust washers greased into place on the machined bosses

inside the case. It was just asking to all fall apart during assembly. Nor was there very much access or space to manoeuvre things, the gearbox casing itself is surprisingly small at around 8 inches / 200mm long.

The

workshop manual says:

With

the aid of thick grease position the bronze layshaft thrust washers.

See

that there are twenty-seven needle rollers at each end of the layshaft cluster.

Locate them with thick grease.

Fit

abutment ring into the front of the cluster and lower the cluster complete with

dummy shaft into the casing, and then fit the rear floating thrust washer.

< next there's a long bit about installing the mainshaft and bearings >

Invert

gearbox and insert layshaft spindle through the rear of the casing, ensuring

that the thrust washers at each end are correctly positioned.

It sounds

fairly easy in print, and I’m sure that back in the day the people in the

factory were very adept at putting these things together, but it could all have

gone horribly wrong. I don’t think it did. I hope not, anyway.

|

| That Layshaft |

The thing is that I didn’t find anything wrong that could have been

the cause of the rattly first gear. I’ve yet to install and run the gearbox to

finally find out if it’s gone away or not, or even if that layshaft fell into place

nicely and properly.

Anyway.

I hope you find that interesting.

Now,

what has that got to do with SmartCAM and CADCAM?

While working

on the gearbox the thought occurred to me of the machining of those things

back in 1962. They may or may not have been machined on NC equipment, but it is

highly probable that they were.

The machines

and controls were rather different to those we know today – the controls were

generally large cabinets installed alongside the machine. The

interface to the outside world was normally via a paper tape reader. But things were fundamentally the

same as today – throw a set of the right bits and bytes at the controller

in the correct order and all will be fine.

We're comparatively spoiled by the CAM system technology that we have available today.

We're comparatively spoiled by the CAM system technology that we have available today.

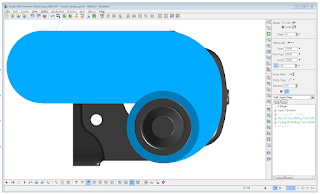

|

| SmartCAM Holemaking Process |

We

take all of the SmartCAM functionality, toolpath modeling, graphics, visualisation, error checking,

ease of creating quality CNC code and much more for granted, don’t we. Back in ‘62 there wasn’t

a CAM system graphics monitor in sight ( somebody will correct me about that if I am wrong ).

|  |

|

|

Computer-aided programming existed, but nothing like we know it. And you can bet that there

was also a whole lot of manual code writing also being done, all that math and trig calculation. For example, one of my own treasured memories ( not from the 60's, I hasten to add ) is of manually programming the facing of large circular flanges for a machine that didn't have circular interpolation. I still have my Casio FX-39 that I used at the time.

Computer-aided programming existed, but nothing like we know it. And you can bet that there

was also a whole lot of manual code writing also being done, all that math and trig calculation. For example, one of my own treasured memories ( not from the 60's, I hasten to add ) is of manually programming the facing of large circular flanges for a machine that didn't have circular interpolation. I still have my Casio FX-39 that I used at the time.Machinery, CNC programming and software of whatever period is all very fascinating to contemplate, don’t you think?

I'm going to leave the detail of NC & CNC programming experiences over the years

and decades for the content of a future blog post.

Some say that business and pleasure shouldn't be mixed. Clearly I've done that here. It is as well that I enjoy my work with SmartCAM, CAM and my motorhead activities.

My next / current project: spraying up the Rapier Wheels before fitting new rubber, work on some new SmartCAM demonstration videos and starting to tackle a rather rusty Citroen GS.

Some say that business and pleasure shouldn't be mixed. Clearly I've done that here. It is as well that I enjoy my work with SmartCAM, CAM and my motorhead activities.

My next / current project: spraying up the Rapier Wheels before fitting new rubber, work on some new SmartCAM demonstration videos and starting to tackle a rather rusty Citroen GS.

Take

care.

Have a great day / evening / weekend.

Talk CAM with us. We're at:

Have a great day / evening / weekend.

Talk CAM with us. We're at:

+1 (541) 344-4563

No comments:

Post a Comment